The Importance of Efficiency in Industrial Processes

Efficiency in industrial processes is not just a buzzword; it is a fundamental driver of competitiveness, profitability, and sustainability. In the realm of manufacturing, where margins can be razor-thin, the ability to produce high-quality products at lower costs is paramount. Aluminium casting, a process integral to many industrial applications, is no exception. Enhancing efficiency in aluminium casting can lead to significant gains in production speed, material usage, and energy consumption. This, in turn, reduces operational costs and enhances the overall value proposition for manufacturers.

Moreover, efficient processes are often synonymous with higher quality. In aluminium casting, precision and consistency are critical. Flaws or variations can lead to product failures, increased waste, and additional costs for rework. By streamlining the casting process, manufacturers can achieve more consistent outcomes, ensuring that each cast component meets stringent quality standards. This not only bolsters the reliability of the final products but also enhances the reputation of the manufacturing entity.

Efficiency also plays a crucial role in meeting environmental and regulatory standards. The industrial sector is under increasing pressure to minimise its ecological footprint. Efficient aluminium casting processes can significantly reduce energy consumption and waste generation, contributing to more sustainable manufacturing practices. This alignment with environmental goals is not only beneficial for the planet but also for the company’s public image and compliance with regulations.

Current Trends in Aluminium Casting Technology

The landscape of aluminium casting technology is evolving rapidly, driven by the need for greater efficiency, precision, and sustainability. One of the prominent trends in this field is the adoption of advanced simulation and modelling tools. These technologies allow manufacturers to virtually prototype and optimise casting processes before actual production begins. By simulating the flow of molten aluminium and predicting potential defects, companies can fine-tune their processes, reducing trial-and-error and enhancing overall efficiency.

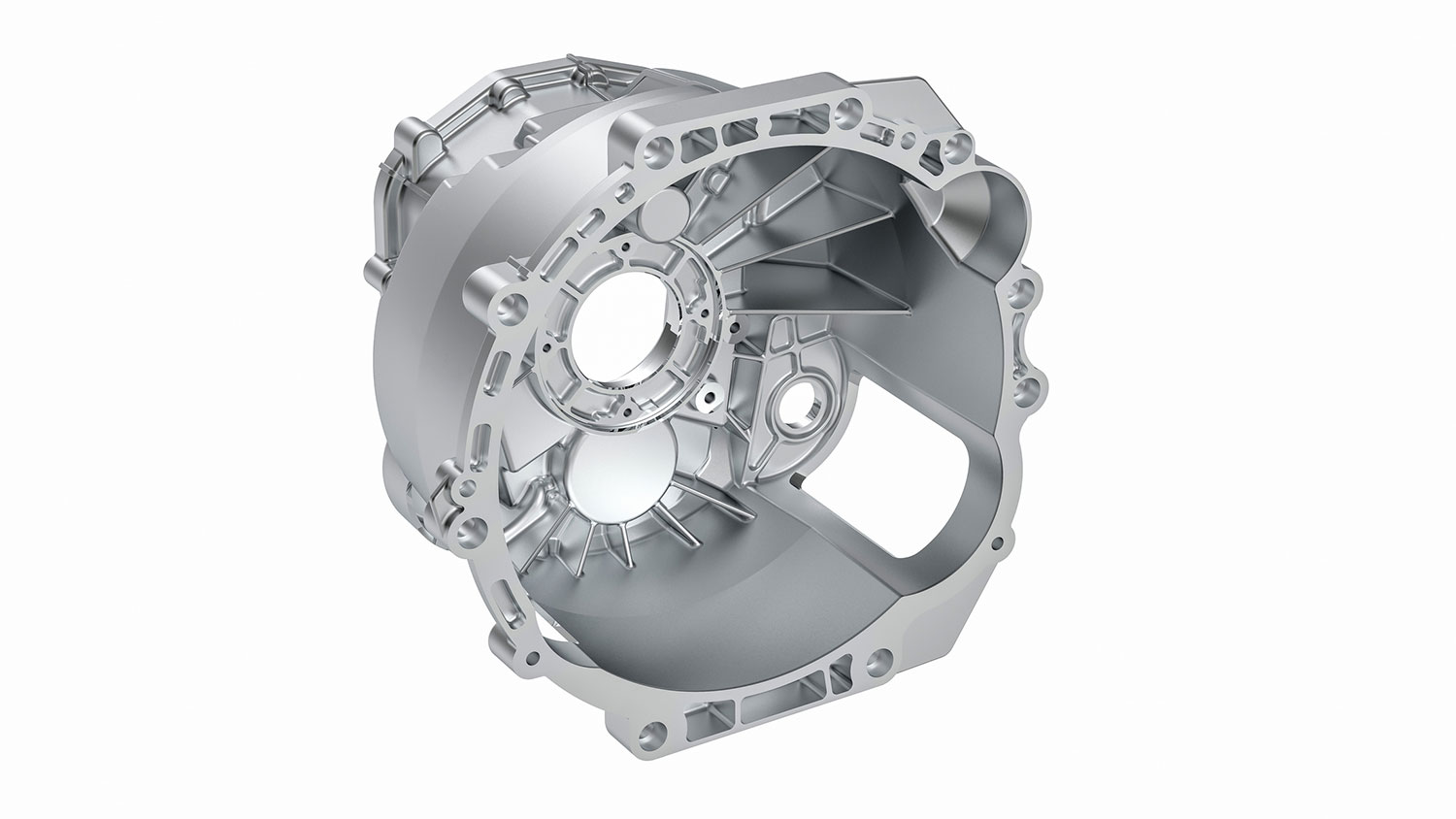

Another significant trend is the integration of additive manufacturing techniques with traditional casting processes. Hybrid approaches that combine 3D printing with casting are opening up new possibilities for complex geometries and intricate designs that were previously challenging or impossible to achieve. This not only expands the design flexibility for engineers but also streamlines the manufacturing process by reducing the need for multiple steps and secondary operations.

Furthermore, there is a growing emphasis on the use of advanced materials and alloys in aluminium casting. Innovations in alloy compositions are enabling the production of components with superior mechanical properties, such as increased strength, durability, and heat resistance. These advancements are particularly beneficial for industries like aerospace and automotive, where performance demands are exceptionally high. By leveraging these advanced materials, manufacturers can produce parts that are not only more efficient to manufacture but also offer enhanced performance in their end-use applications.

Innovations Driving Efficiency in Aluminium Casting

Innovations in aluminium casting are revolutionising the industry by significantly enhancing efficiency. One of the most impactful advancements is the development of high-pressure die casting (HPDC) techniques. HPDC allows for the rapid injection of molten aluminium into a mould under high pressure, resulting in fast cycle times and high production rates. This method is particularly advantageous for large-scale production, offering both speed and precision. The ability to produce complex shapes with tight tolerances in a single step reduces the need for secondary machining, further boosting efficiency.

Another groundbreaking innovation is the use of advanced cooling techniques. Traditionally, cooling has been a time-consuming part of the casting process. However, new methods such as conformal cooling channels, created using 3D printing, are transforming this aspect. These channels are designed to closely follow the contours of the mould, providing more uniform and faster cooling. This not only shortens the overall cycle time but also improves the quality of the cast parts by reducing thermal stresses and distortions.

Furthermore, the incorporation of real-time monitoring and control systems is playing a pivotal role in driving efficiency. By using sensors and data analytics, manufacturers can continuously monitor the casting process, detecting anomalies and making adjustments on the fly. This proactive approach minimises defects and reduces waste, ensuring that each cast part meets the desired specifications. The integration of the Internet of Things (IoT) and machine learning algorithms into casting operations is enabling predictive maintenance, where potential issues are identified and addressed before they lead to downtime, further optimising the efficiency of the production line.

The Role of Automation and Robotics

Automation and robotics are at the forefront of transforming aluminium casting operations, driving unprecedented levels of efficiency. The integration of robotic systems in the casting process has significantly reduced the reliance on manual labour, which is often prone to errors and inconsistencies. Robots can perform repetitive tasks with high precision and consistency, such as mould handling, metal pouring, and part extraction. This not only accelerates the production process but also enhances the quality of the final products by ensuring uniformity across all cast parts.

Advanced robotics is also enabling greater flexibility in manufacturing. Collaborative robots, or cobots, are designed to work alongside human operators, augmenting their capabilities and handling tasks that are either too dangerous or monotonous for humans. These cobots can be easily programmed and reconfigured for different tasks, making them ideal for dynamic production environments that require frequent changes. By offloading repetitive and hazardous tasks to robots, human workers can focus on more complex, value-added activities, thereby further boosting overall productivity.

Moreover, automation extends beyond just the physical handling of materials. Automated systems are now being used for quality inspection and control. Vision systems and artificial intelligence (AI) algorithms can inspect cast parts for defects in real time, ensuring that only those that meet strict quality standards proceed to the next stage. This reduces the likelihood of defective products reaching the market and minimises the cost associated with rework and scrap. The combination of robotics and AI-driven inspection systems is setting new benchmarks for efficiency and quality in aluminium casting.

Sustainable Practices in Aluminium Casting

Sustainability is becoming an integral aspect of modern manufacturing, and aluminium casting is no exception. The drive towards greener practices is influenced by both regulatory pressures and a growing consumer demand for environmentally responsible products. One of the key areas where sustainability is being addressed is in the reduction of energy consumption. Advanced melting technologies, such as induction furnaces, are more energy-efficient compared to traditional gas-fired furnaces. These technologies not only reduce energy costs but also lower greenhouse gas emissions, contributing to a smaller carbon footprint.

Recycling is another critical component of sustainable aluminium casting. Aluminium is highly recyclable, and the industry is increasingly adopting closed-loop recycling systems where scrap aluminium is collected, melted, and reused in new casting processes. This not only conserves natural resources but also significantly reduces the energy required for production, as recycling aluminium consumes only a fraction of the energy needed to produce new aluminium from bauxite ore. By maximising the use of recycled materials, manufacturers can achieve substantial environmental benefits while also reducing costs.

Water usage and waste management are also being improved through innovative practices. Advanced filtration and treatment systems are being implemented to recycle water used in the cooling and cleaning processes, minimising water consumption and reducing the discharge of pollutants. Additionally, the development of environmentally friendly binders and coatings for moulds and cores is reducing the release of volatile organic compounds (VOCs) and other harmful substances. By adopting these sustainable practices, the aluminium casting industry is making significant strides towards more eco-friendly manufacturing, aligning with global sustainability goals.

Case Studies: Successful Implementation of Efficient Casting Techniques

Several companies around the world are leading the charge in implementing efficient aluminium casting techniques, setting benchmarks for the industry. One notable example is Tesla, which has revolutionised automotive manufacturing with its use of giga casting. Tesla’s innovative approach involves using massive die-casting machines to produce large, single-piece aluminium components for its vehicles. This technique has significantly reduced the number of parts and assembly steps required, leading to faster production times, lower costs, and improved structural integrity of the vehicles.

Another success story is that of General Electric (GE) Aviation, which has embraced advanced casting techniques to produce jet engine components. GE has leveraged additive manufacturing in conjunction with traditional casting to create complex, high-performance parts that are lighter and more efficient. By using 3D-printed moulds and cores, GE has been able to achieve intricate geometries and reduce material waste. This hybrid approach has not only enhanced the efficiency of their production processes but also resulted in significant improvements in engine performance and fuel efficiency.

In the aerospace sector, Airbus has also made significant strides in efficient aluminium casting. The company has implemented advanced simulation and modelling tools to optimise its casting processes, reducing the time and cost associated with prototyping. By simulating the flow of molten aluminium and predicting potential defects, Airbus has been able to fine-tune its processes, achieving higher quality and consistency in its cast components. These advancements have been instrumental in supporting Airbus’s commitment to sustainability and innovation in aerospace manufacturing.

Challenges Facing the Aluminium Casting Industry

Despite the numerous advancements and innovations, the aluminium casting industry faces several challenges that must be addressed to fully unlock its potential. One of the primary challenges is the high initial investment required for advanced casting technologies and automation. Small and medium-sized enterprises (SMEs) often struggle to afford the upfront costs associated with modernising their facilities. This financial barrier can hinder the widespread adoption of efficient and sustainable practices, limiting the overall progress of the industry.

Another significant challenge is the shortage of skilled labour. While automation and robotics can perform many tasks, the industry still relies on skilled workers for tasks such as process optimisation, maintenance, and quality control. The current workforce gap is exacerbated by the rapid pace of technological advancements, which require continuous upskilling and training. Addressing this skills gap is crucial for ensuring that the industry can effectively leverage new technologies and maintain high standards of quality and efficiency.

Environmental regulations and compliance also pose challenges for the aluminium casting industry. As governments worldwide implement stricter environmental standards, manufacturers must adapt their processes to meet these requirements. This often involves significant changes to existing operations, such as adopting greener technologies, improving waste management practices, and reducing emissions. Compliance can be complex and costly, particularly for smaller companies with limited resources. However, failure to meet regulatory standards can result in fines, legal issues, and reputational damage, making it imperative for the industry to navigate these challenges effectively.

Future Predictions for Aluminium Casting Efficiency

The future of aluminium casting efficiency looks promising, with several emerging trends and technologies set to transform the industry. One of the key predictions is the increased adoption of artificial intelligence (AI) and machine learning. These technologies will enable more sophisticated data analytics and process optimisation, allowing manufacturers to predict and prevent defects, optimise material usage, and enhance overall production efficiency. AI-driven predictive maintenance will also become more prevalent, reducing downtime and extending the lifespan of casting equipment.

Another significant trend is the continued integration of additive manufacturing with traditional casting processes. As 3D printing technology advances, it will become increasingly feasible to produce complex moulds and cores with greater precision and at lower costs. This hybrid approach will offer unparalleled design flexibility and efficiency, enabling manufacturers to create highly intricate and customised components with minimal waste. The synergy between additive manufacturing and casting will open up new possibilities for innovation and efficiency in the production of aluminium parts.

Sustainability will remain a central focus, with advancements in green technologies and practices driving further improvements in efficiency. The development of more energy-efficient melting and cooling systems, along with the increased use of recycled aluminium, will contribute to a more sustainable and cost-effective casting process. Additionally, the industry will likely see greater collaboration and sharing of best practices, as companies work together to address common challenges and achieve collective sustainability goals. This collaborative approach will be instrumental in driving continuous improvement and innovation in aluminium casting efficiency.

Conclusion: Embracing Change for a Sustainable Future

The future of industrial aluminium casting is bright, with efficiency at the heart of its transformation. The advancements in casting technologies, the integration of automation and robotics, and the adoption of sustainable practices are paving the way for a more efficient and environmentally responsible industry. However, realising this potential requires a commitment to overcoming challenges such as high initial investments, skills shortages, and regulatory compliance.

By embracing these changes and investing in innovation, the aluminium casting industry can unlock significant benefits, from reduced production costs and enhanced product quality to improved sustainability and competitiveness. Companies that lead the way in adopting efficient casting techniques will not only gain a competitive edge but also contribute to a more sustainable future for manufacturing. The journey towards unlocking efficiency in aluminium casting is ongoing, and the industry must continue to evolve and adapt to stay ahead in an ever-changing landscape.

As we look to the future, it is clear that the key to success lies in embracing change, leveraging new technologies, and fostering a culture of continuous improvement. By doing so, the aluminium casting industry can achieve new heights of efficiency and sustainability, shaping the future of manufacturing for generations to come.